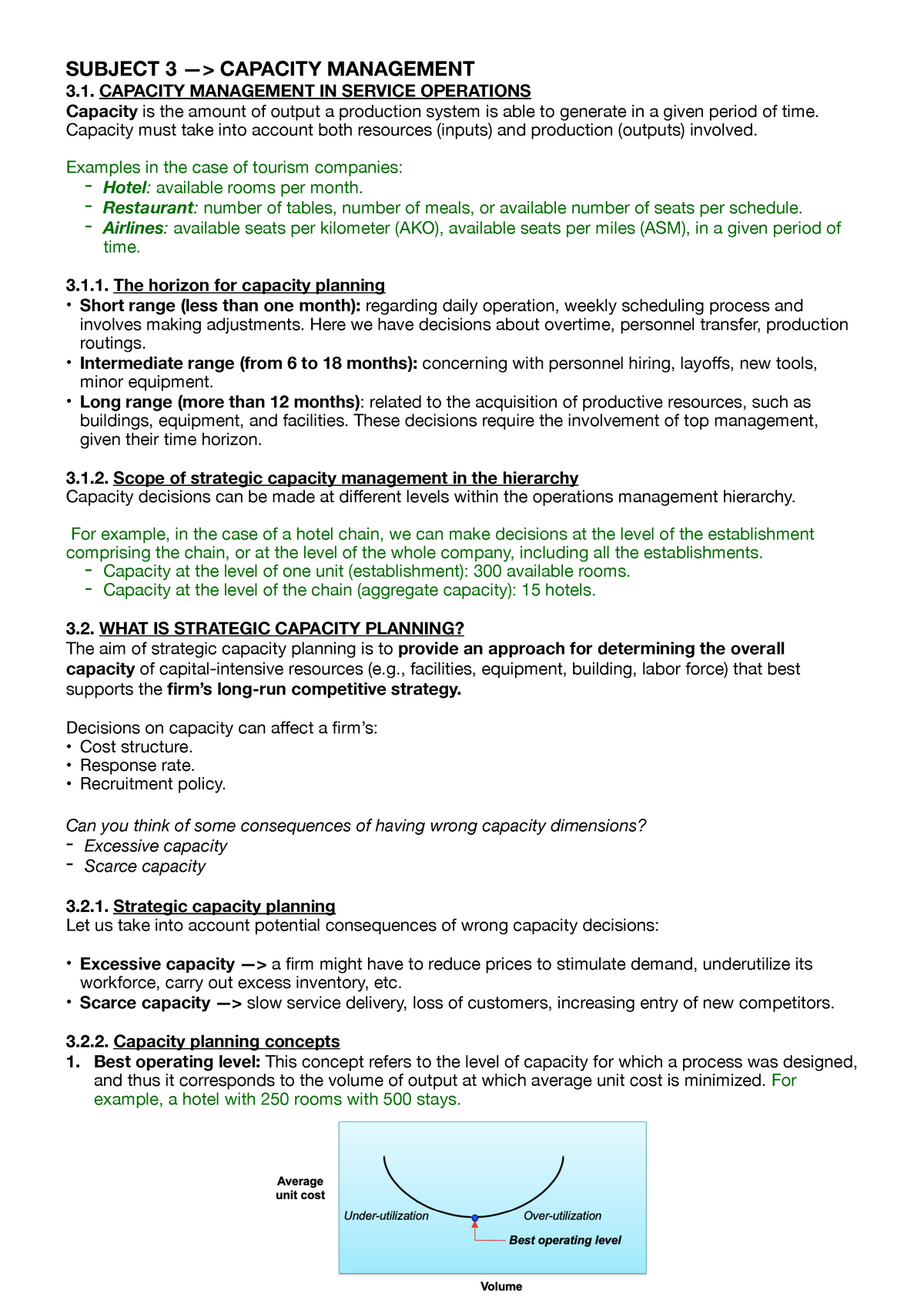

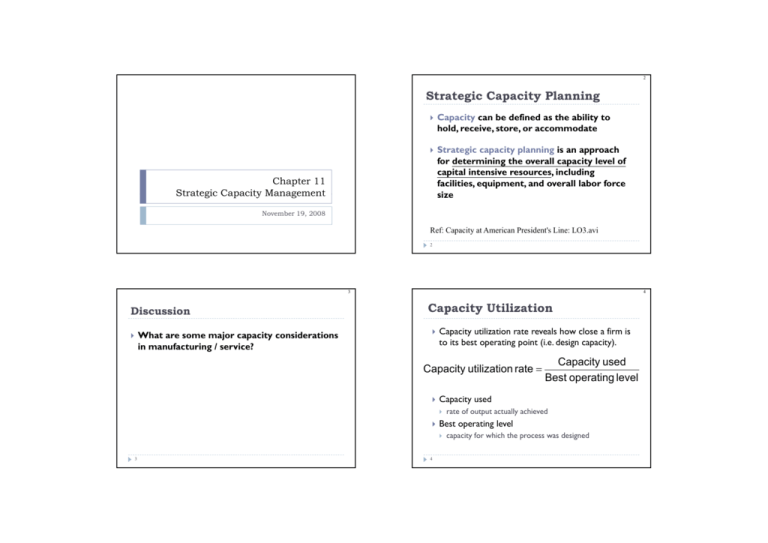

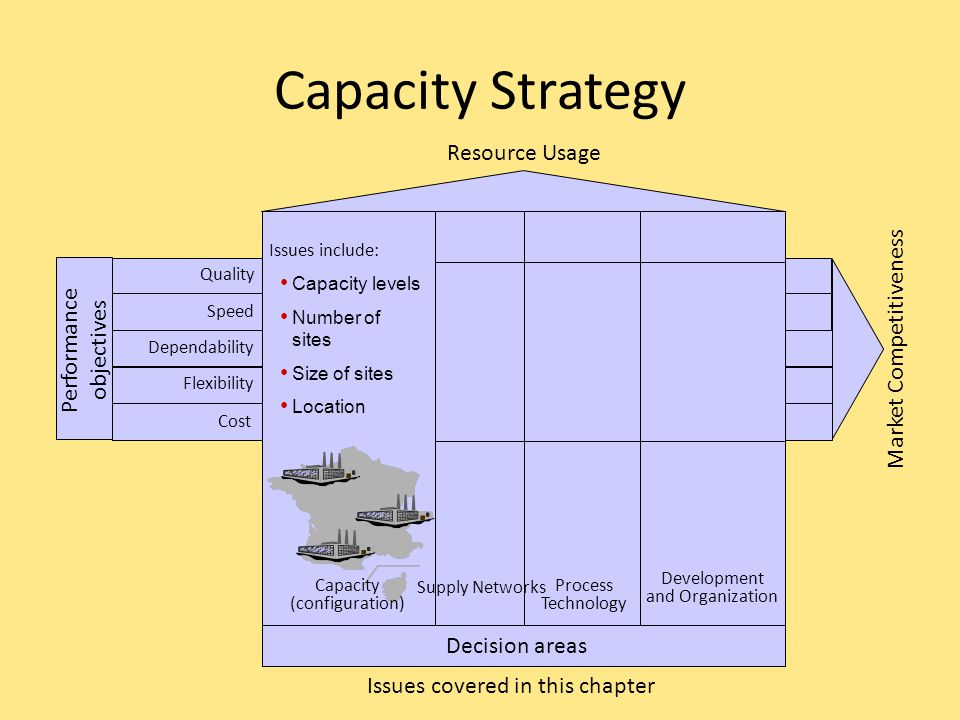

Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization Two terms of design capacity and effective capacity are used extensively in the context of capacity planning The first is the maximum work that is completed in a specific period by an organization, and the latter is theWhen dealing with more than one product, it is best to measure capacity in terms of each product For example, the capacity of a firm is to either produce 100 microwaves or 75 refrigerators This is less confusing than just saying the capacity is 100 or 75 Another method of measuring capacity is by referring to the availability of inputs This is usually more helpful if we are dealing with several type of output Note that one specific measure of capacityOn an assembly line in a car factory, for example, a painting robot might be able to paint 10,000 cars in a day Considering this type of capacity is also important for workforce capacity planning;

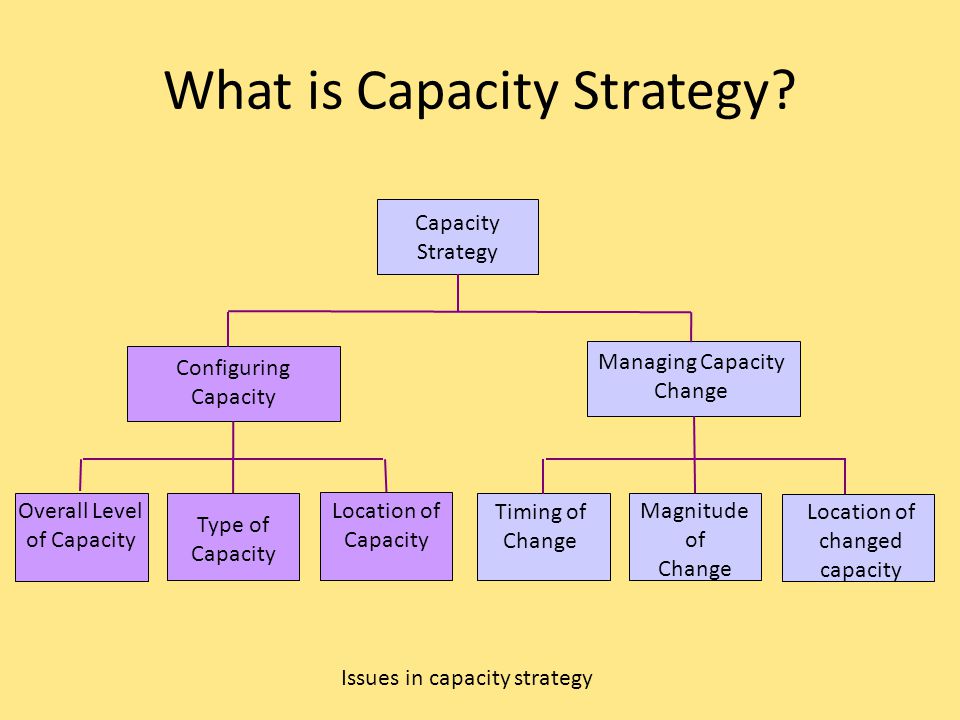

4 Capacity Strategy

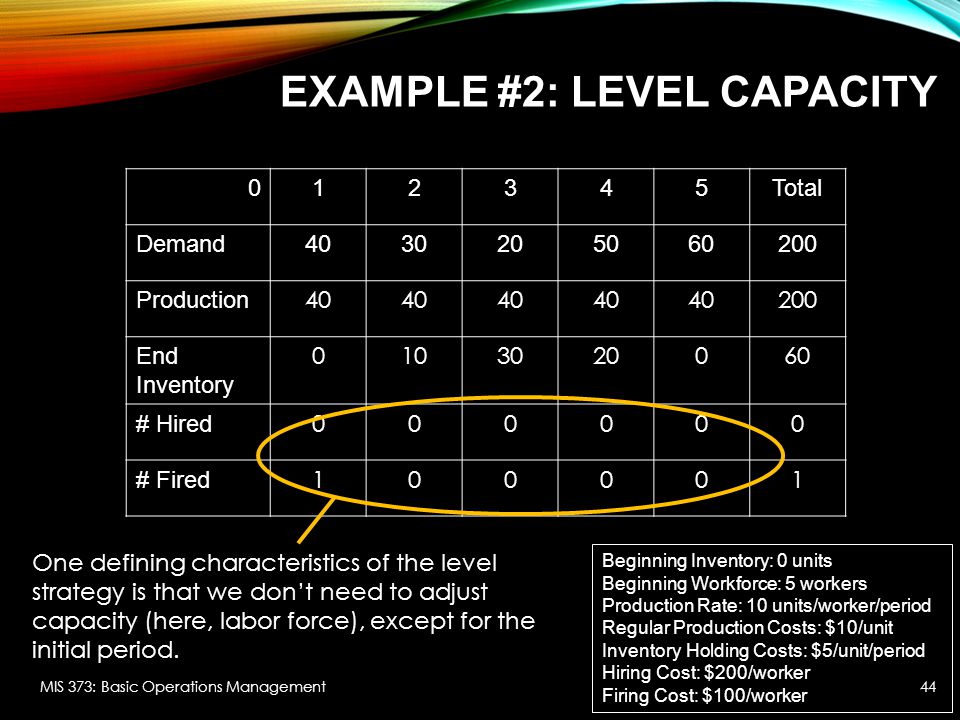

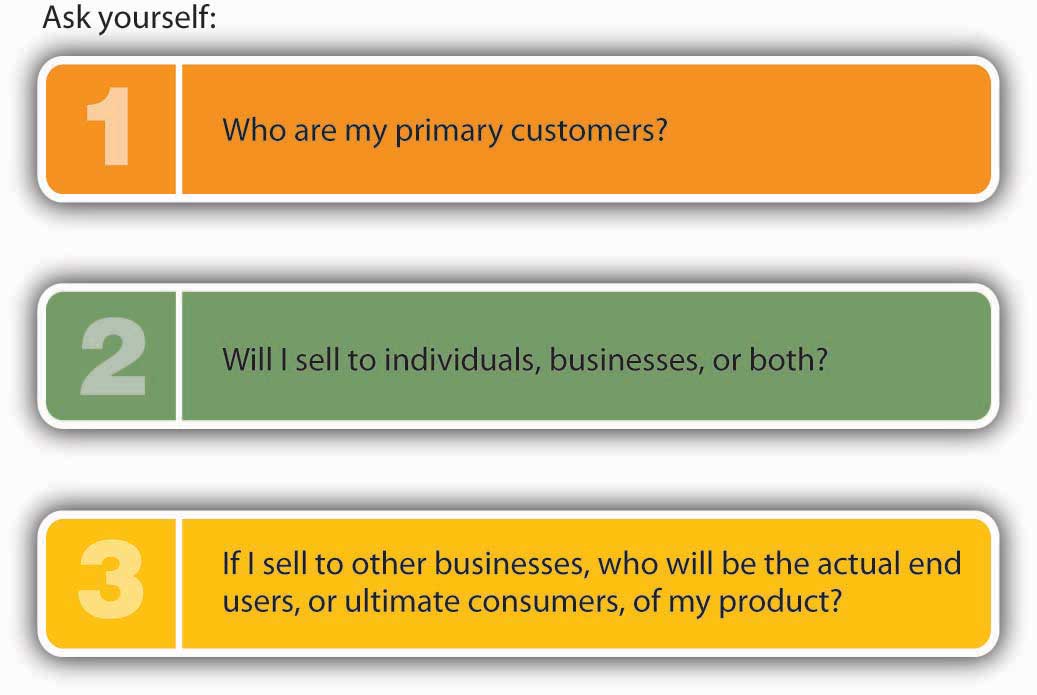

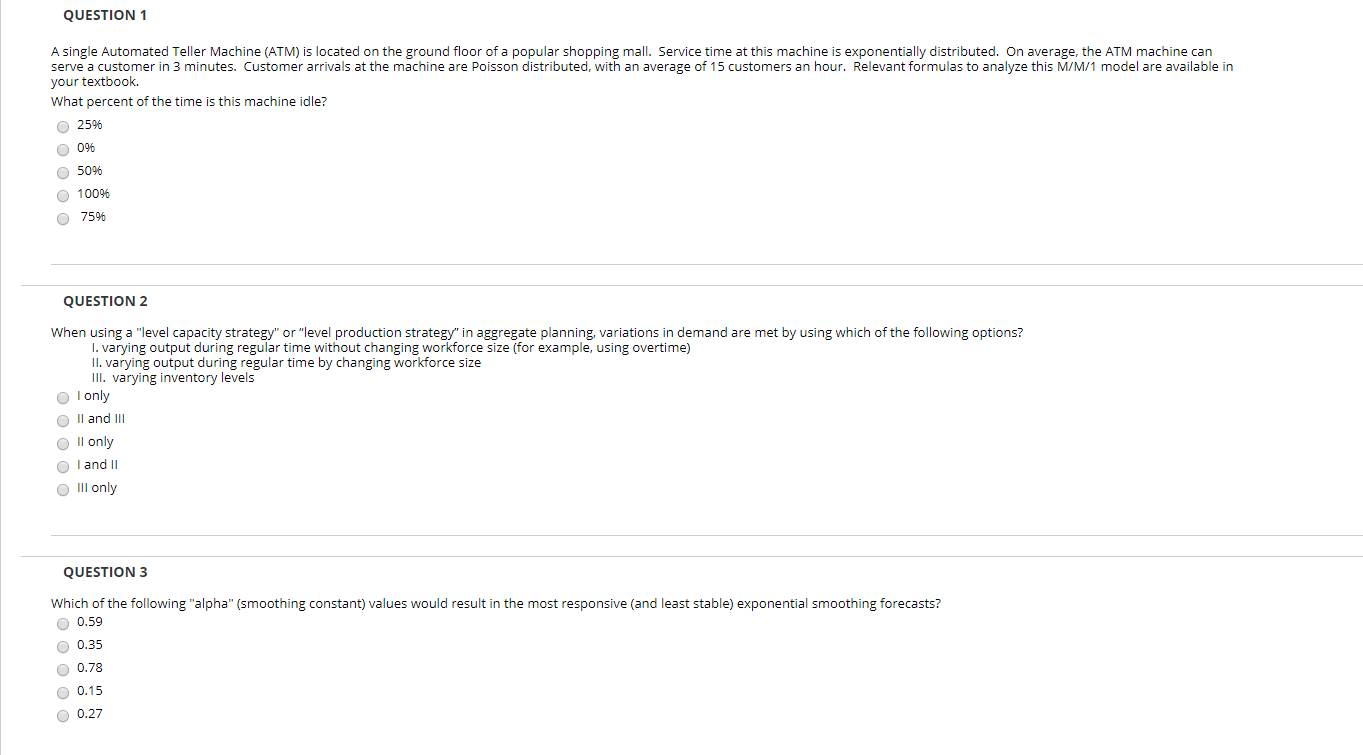

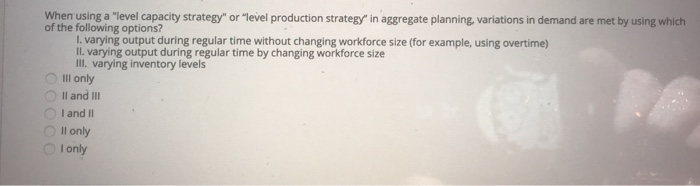

Level capacity strategy example

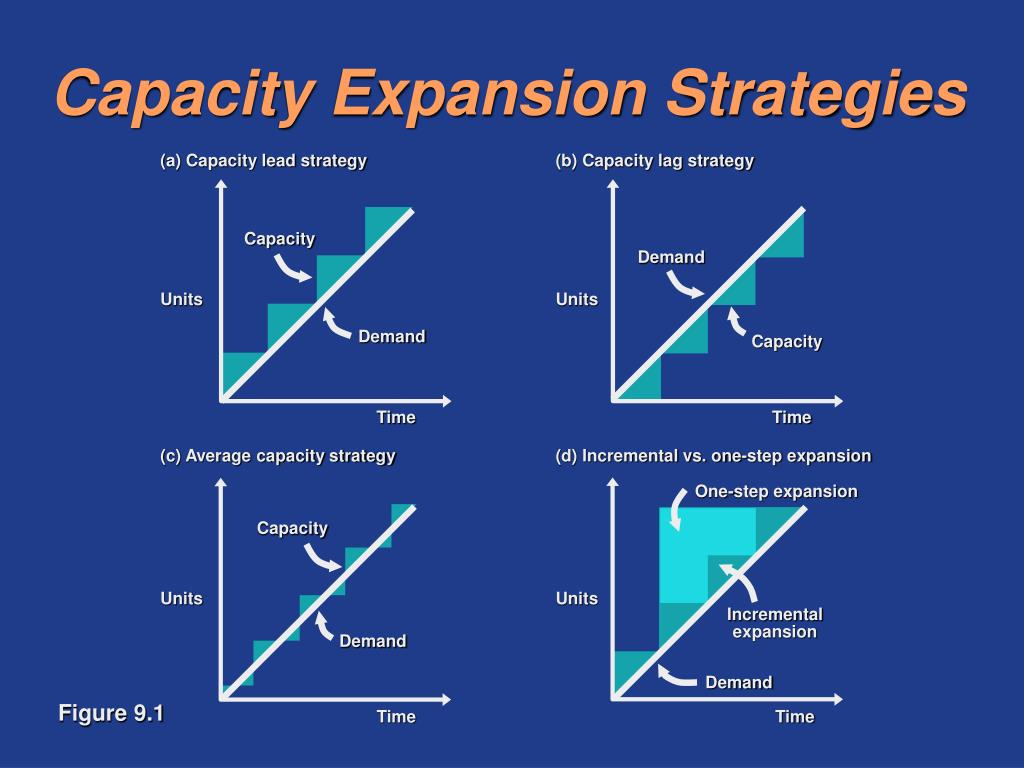

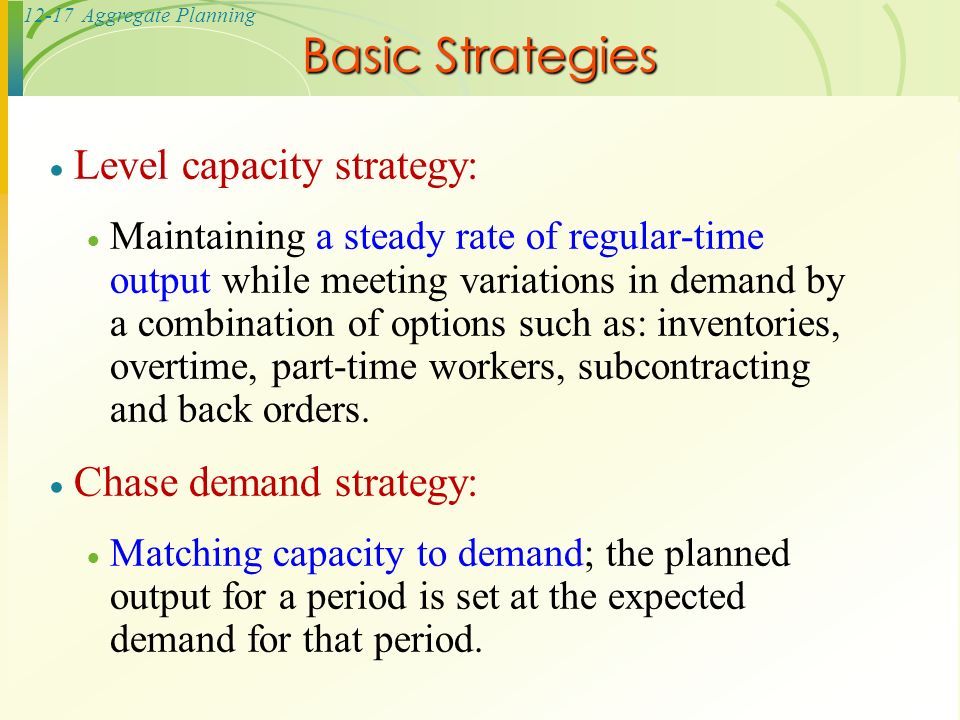

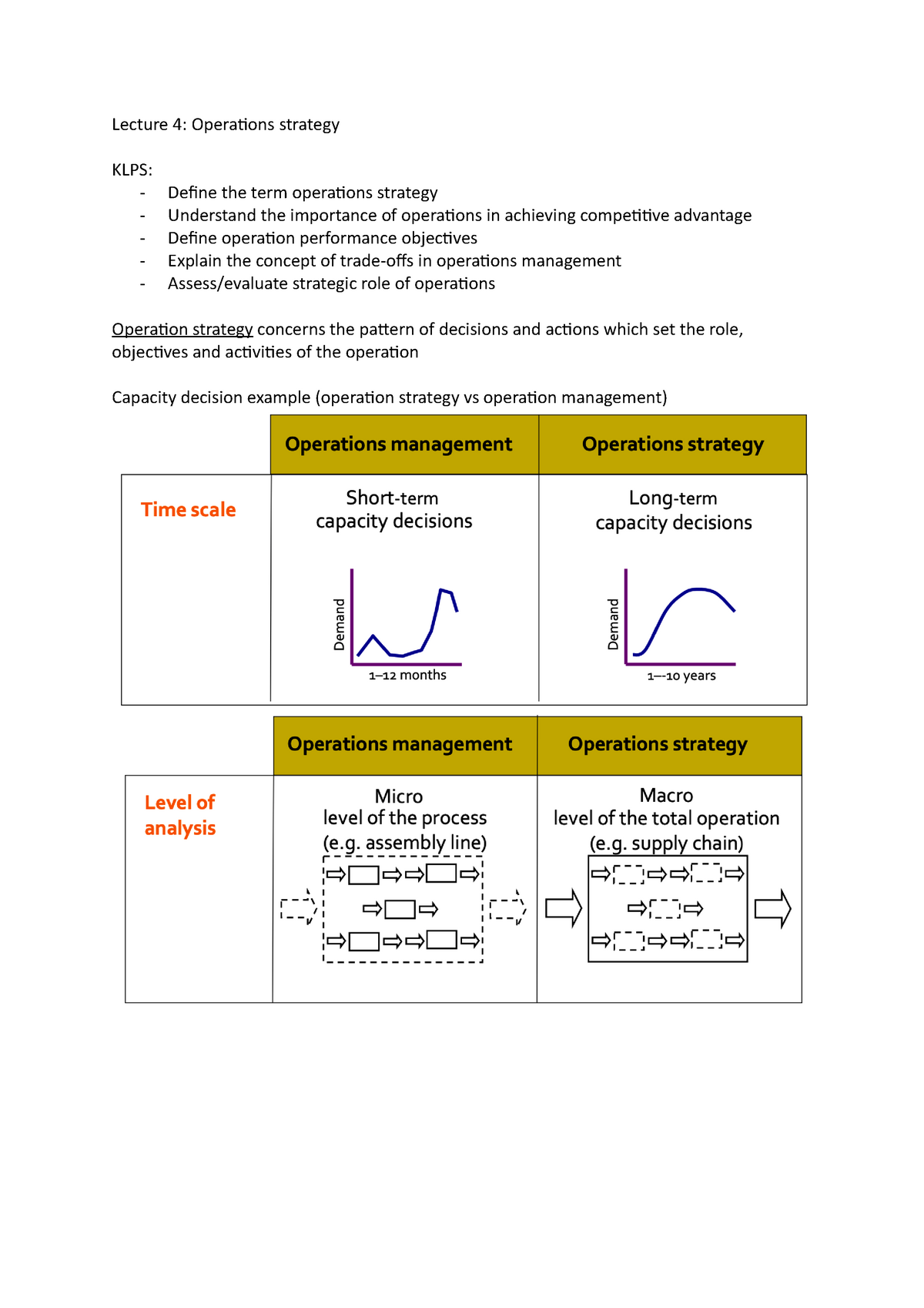

Level capacity strategy example-Primarily level capacity and chase capacity or a mix of both are the main methods adopted by firms In addition a demand management strategy can also be added to the mix bringing a new dimension to operations strategy Level strategy can be defined as a planning strategy that sustains constant production This incorporates varying customer deliver lead time, keeping Lead strategy is planning to have enough resources to meet your demand forecasts Lead strategy assumes more risk than lag strategy For example, if you hire new workers and don't wind up with the orders you were predicting, you could lose money paying employees to sit around The major benefit of this strategy is that if you do have a sudden uptick in orders, you will most

Fast Track Strategic Planning For Nonprofits Nonprofit Essentials

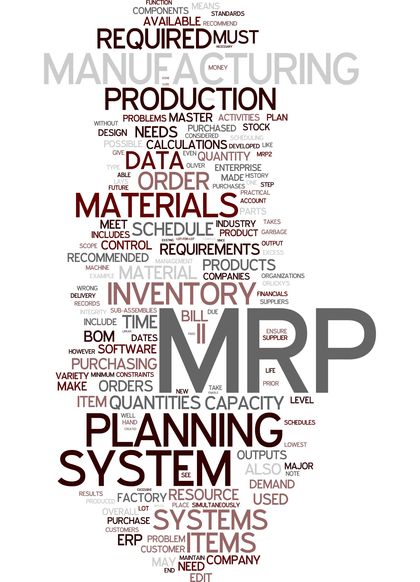

MPS Planning Example ` MPS plan for model A of the previous example ` Maketostock environment ` No safetystock for enditems ⌧I t = I t1 Q t –max{F t,O t} ⌧I t = enditem inventory at the end of week t ⌧Q t = manufactured quantity to be completed in week t ⌧F t = forecast for week t ⌧O t = customer orders to be delivered in week t forecast FtA Language of Instruction Introduce By using this strategy, the company can carry out a strategy of "stock piling" The production manager using this strategy can make a quick decision He does not have to wait for long to prepare and implement the decision The demand of the market is completely served by using this strategy

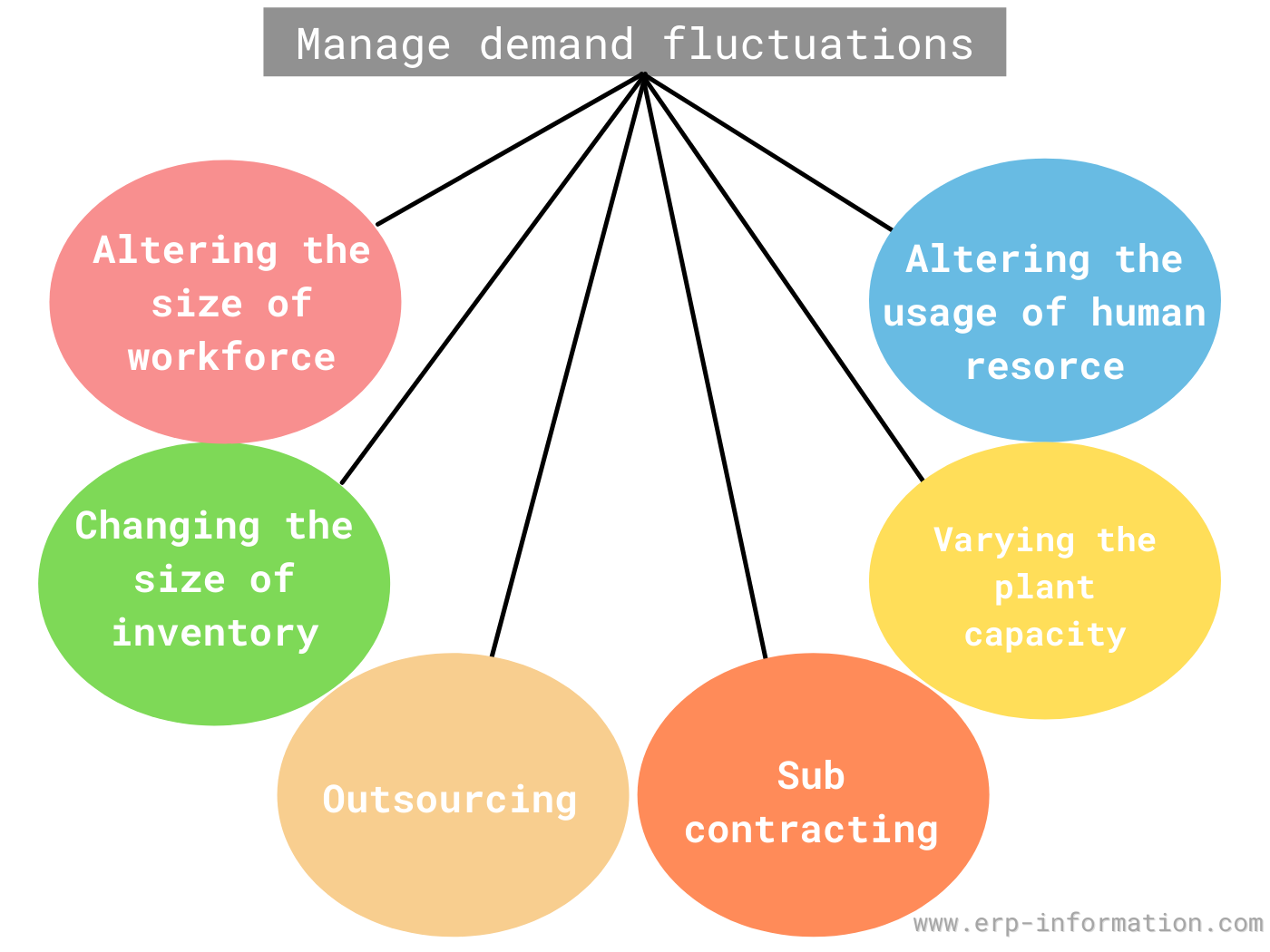

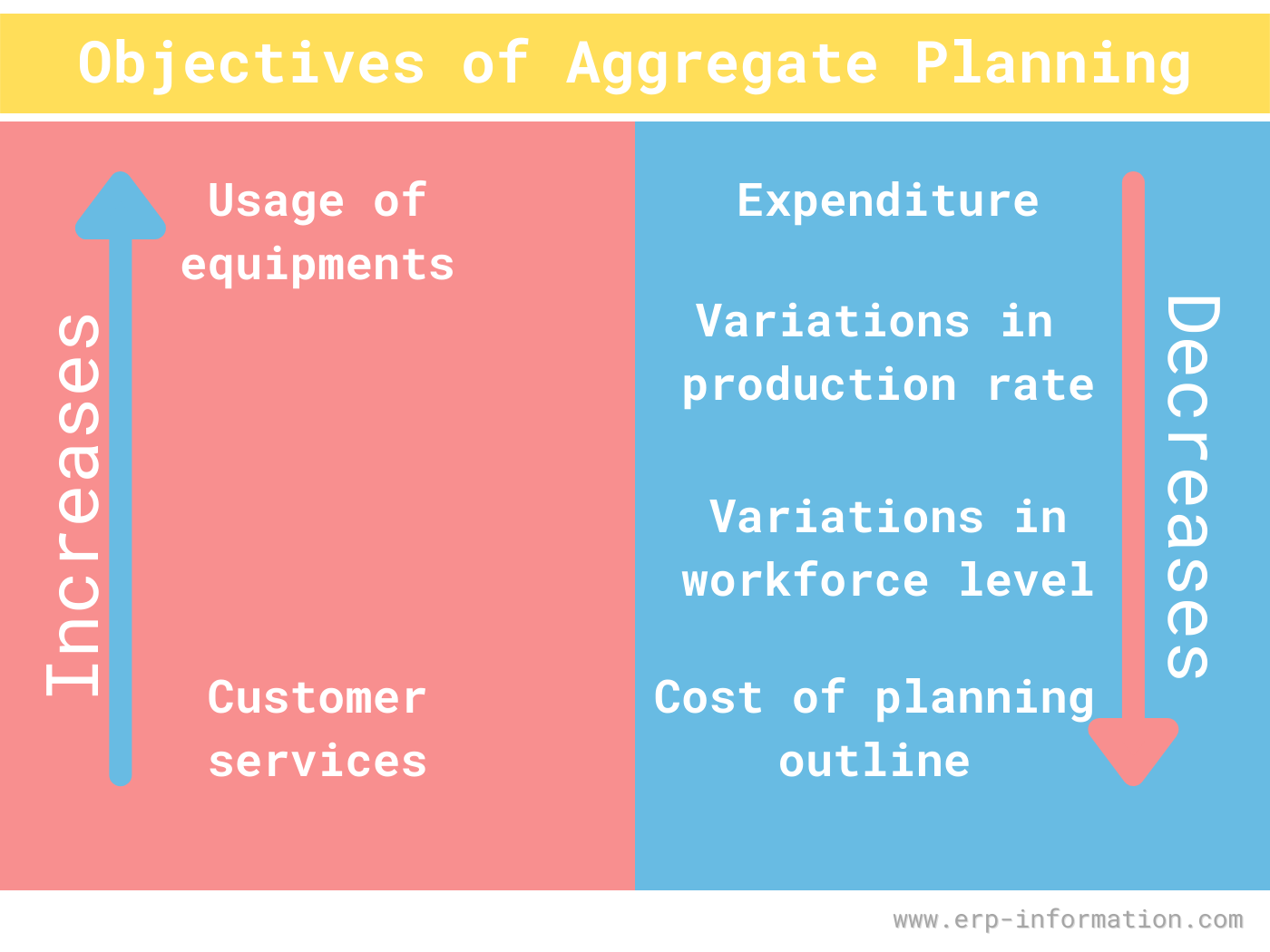

Decision diagram Logical diagram of the CE's strategymaking in Egypt 06The level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to follow The company's strategy aims to eliminate capacity constraints through the utilization of qualitative and quantitative forecasting methods References Makridakis, S, (08) Forecasting methods and applications New York John Wiley & Sons Nahmias, S (11) Perishable inventory systems New York Springer Science & Business Media Get your 100% original paper on any

Capacity management for an IT service This may include resources such as network, data center space, cooling, power, cpu and disk space For example, a software service that offers an SLA to customers plans the capacity required to meet service levels based on sales forecastsLevel capacity strategy The organisation produces or manufactures at a constant rate of output avoiding any changes or fluctuations within customer demand levels This frequently implies stockpiling or higher holdings of inventory while customer demand levels reduceLevel capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand This may lead to stockpiling or holding of inventory in high quantity, when there is a decrease in the demand level

Capacity Strategy Pdf Economies Of Scale Strategic Management

3 Types Of Capacity Planning Strategies Valq

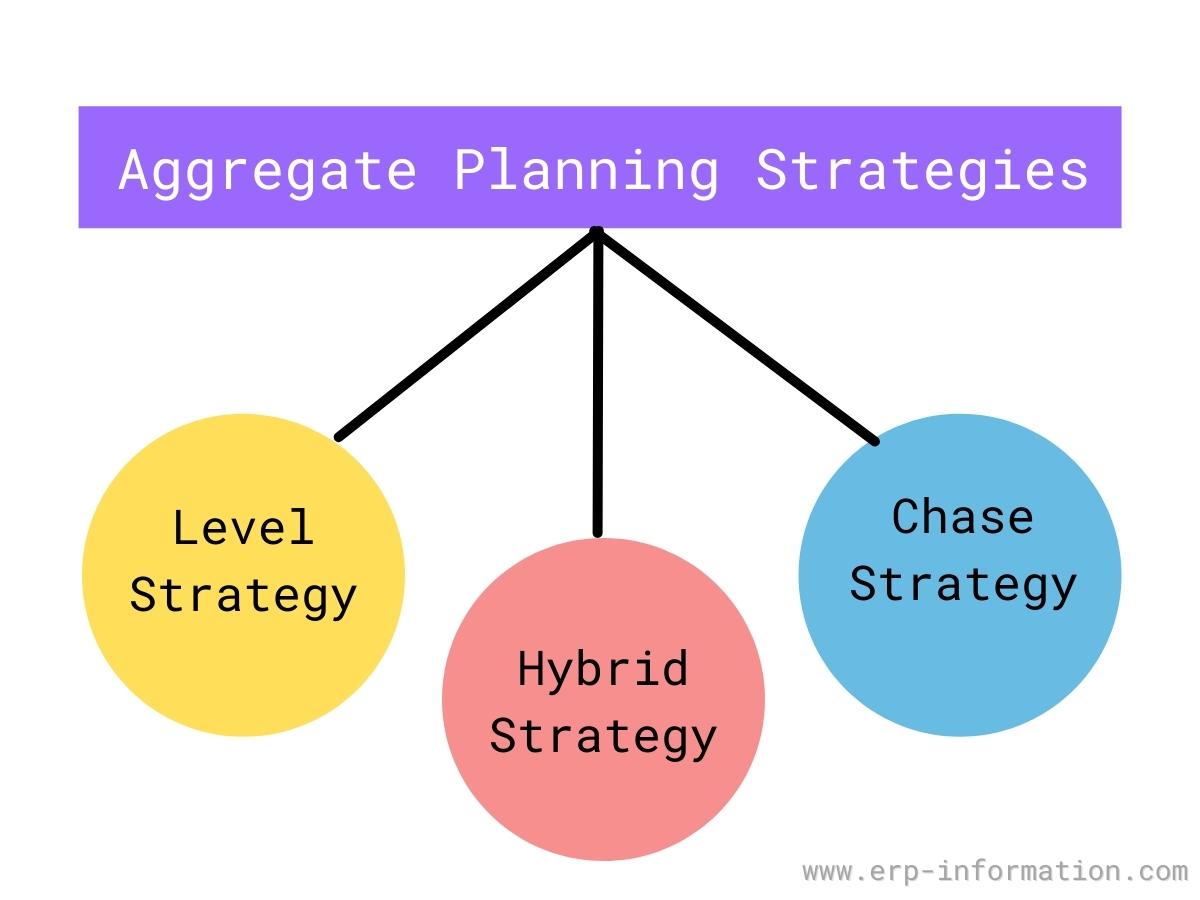

Capacity Planning It's pprove/cancel projectsCapacity Planning Capacity planning is a longterm strategic decision that establishes a firm's overall level of resources It extends over a time horizon long enough to obtain those resourcesusually a year or more for building new facilities or acquiring new businesses Capacity As the name indicates, the Hybrid strategy is an integration of both level and chase strategies to get a better result It maintains a sufficient balance between stock level, recruiting, termination and production rate In the hybrid strategy of aggregate planning, the organizations build up inventory before rising demands It uses backorders to level with high peak periods

Ppt Capacity And Aggregate Planning Powerpoint Presentation Free Download Id

Everything About Capacity Planning Strategies Its Benefits

Scenario Planning Strategy, Steps and Practical Examples By Rami Ali and David Luther Scenario planning helps decisionmakers identify ranges of potential outcomes and impacts, evaluate responses and manage for both positive and negative possibilities By visualizing potential risks and opportunities, businesses can becomeCapacity Building Strategy USAID/Zambia Communications Support for Health Program 2 INTRODUCTION The Communications Support for Health (CSH) program aims to enhance the capacity of the Government of the Republic of Zambia (GRZ) to manage and implement effective national health communications interventions It is expected that enhanced IEC/BCCThis Strategy uses the term 'capacity development' as it is more reflective of the existing reality of the PSNP 2 Community Development Programme (PCDP), have been carrying out capacity development activities that bring potential overlaps and synergies with PSNP, but to date the linkages between the CD aspects of these programmes and PSNP are also weak During the

Capacity Strategy Pdf Economies Of Scale Strategic Management

Institutional Capacity For Designing And Implementing Agricultural And Rural Development Policies And Strategies In Nigeria Ifpri Publications Repository Ifpri Knowledge Collections

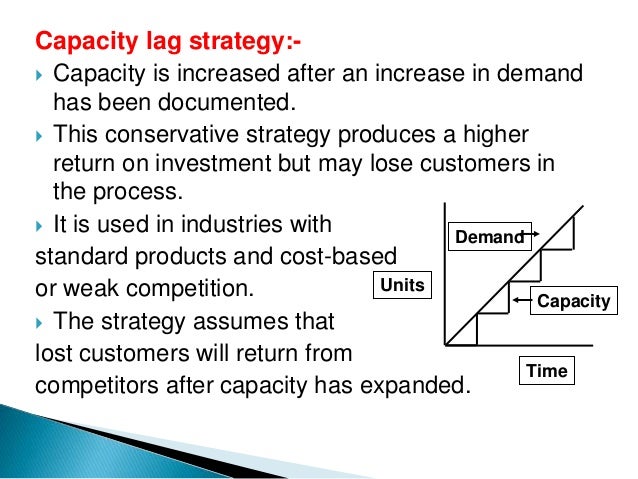

Logical framework analysis EN; Lead Strategy An upfront investment in more capacity that you need This can be done when capacity is inexpensive or difficult to obtain For example, a new vineyard anticipates using less than 10 acres of land in its first 5 years but purchases 100 acres of land as a long term investment in the businessSo, the best example of push promotional strategy is garments and the FMCG sector Where the products are produced and then put on the display for sale While the company keeps on producing new goods even a lot of stock present in the market Further, the push strategy works at the stake of the following cons Production Approximation;

Strategy Under Uncertainty

The Four Perspectives Of The Balanced Scorecard Balanced Scorecard Institute

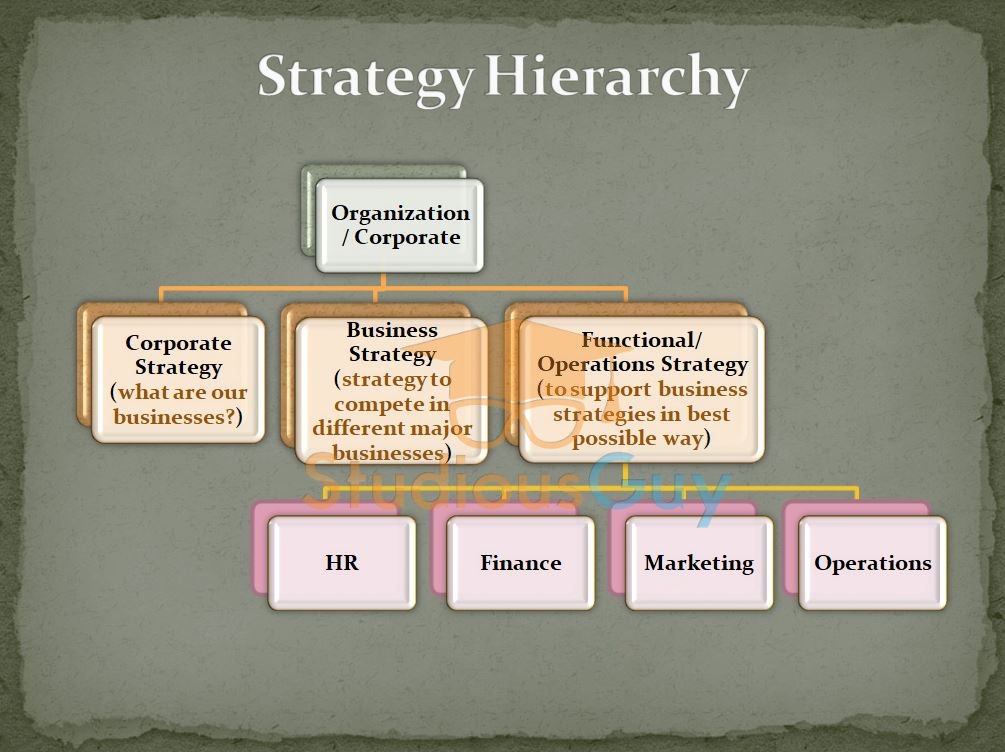

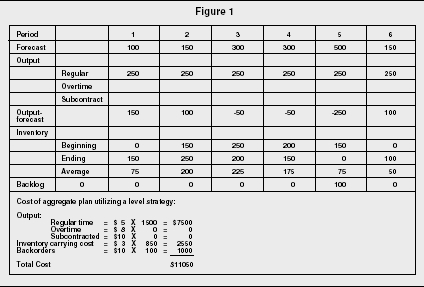

The more appropriate corporatelevel strategy is, the more it would increase the chances for the success of your organization Some of the main differences between corporate and business level strategy are as follows;A level strategy seeks to produce an aggregate plan that maintains a steady production rate and/or a steady employment level In the context of the problem posted by you following the level strategy means incurring additional subcontracting costs at least twice This is to offset the shortfall in production because of the level strategy In order to satisfy changes in customerThe steps are in order Evaporation, Wash, Centrifugation, Grinding, Drying, Sack, Packaging, Shipping

Chapter 4 Strategy And Strategic Planning Strategic Marketing In The Global Forest Industries

Capacity Planning 3 Methods How To Implement Them Optimoroute

This revision video provides an overview of the concept of capacity, capacity utilisation and some of the issues facing businesses operating at low or high u Selecting a capacity alternative most suited to achieving strategic mission 17 THREE STEPS OF CAPACITY PLANNING 18 Determine Service Level Requirements 19 The first step on the capacity planning process is to categorize the work done by systems and to quantify users' expectation for how the work gets down Define workloads 21√100以上 level capacity strategy example 2144Level capacity strategy example For example, let's say you run a flower shop like The Little Posy Co, and Valentine's Day is your busiest time of the year You would use capacity planning to determine if you need to hire more employees, bring on seasonal workers, or A firm should tend toward a levelcapacity strategy, particularly in

Capacity Planning Meaning Classification And Its Goals

Capacity Utilization Definition Example And Economic Significance

At country level managed by the Evaluation Unit EN Example of an objectives diagram and an impact diagram in the context of a sectorbased evaluation Transport EN;The workers on the assembly line are limited by the number of cars orThe use of a level strategy means that a company will produce at a constant rate regardless of the demand level In companies that produce to stock, this means that finished goods inventory levels will grow during low demand periods and decrease during high demand periods In maketoorder or assembletoorder environments the backlog of orders will increase when demand is high and

Is Muni Cz

Capacity Management

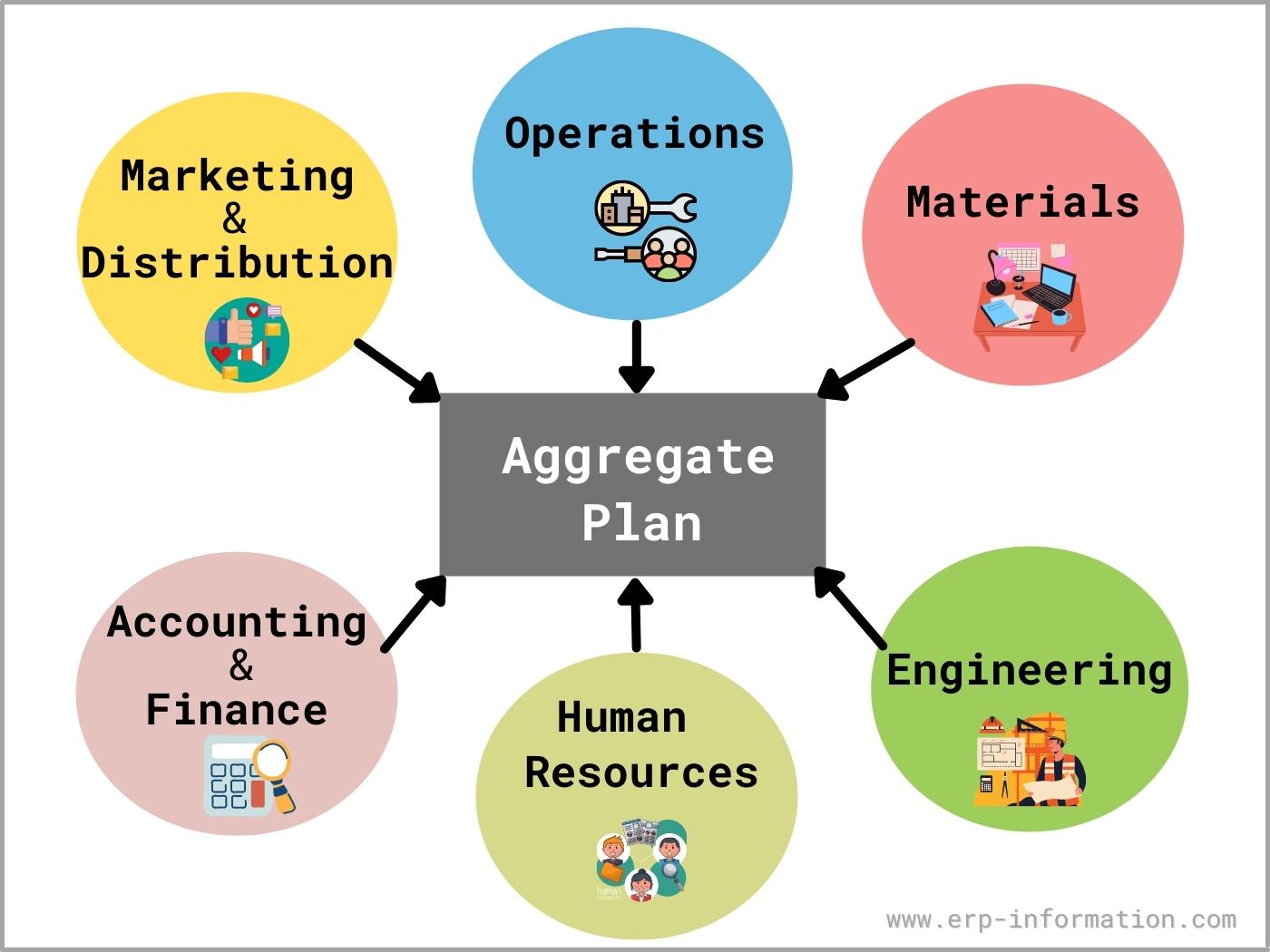

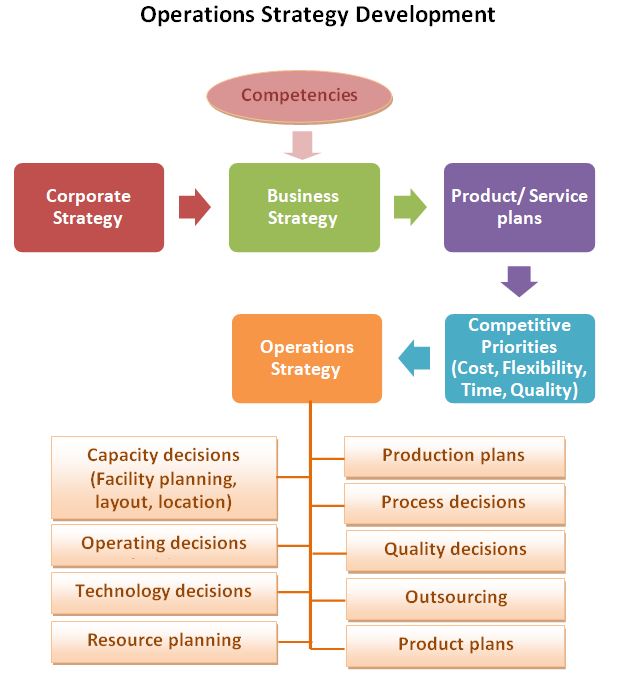

Managers usually design the business strategy to improve the overall performance of the company On the other hand, the mission statement expresses the corporate strategy Home > Projects/Reports > Aggregate Production Planning Example Aggregate Production Planning Example Level Production Strategy We are going to find the requirements for the entire period of the plan and also produce the average amount that is needed per month in order to meet the plan First we are going to determine the total average requirements perRéclament de l'approche basée sur les ressources en stratégie Cette approche repose sur l'idée que la performance supérieure d'une firme s'explique par la possession de ressources et de capacités organisationnelles qui ont des caractéristiques uniques Cette approche connaît un développement théorique important dans le champ de la stratégie depuis le milieu des années

How To Implement Business Capacity Planning Strategies Steps

9 Business Roadmap Examples For Scaling Your Organization

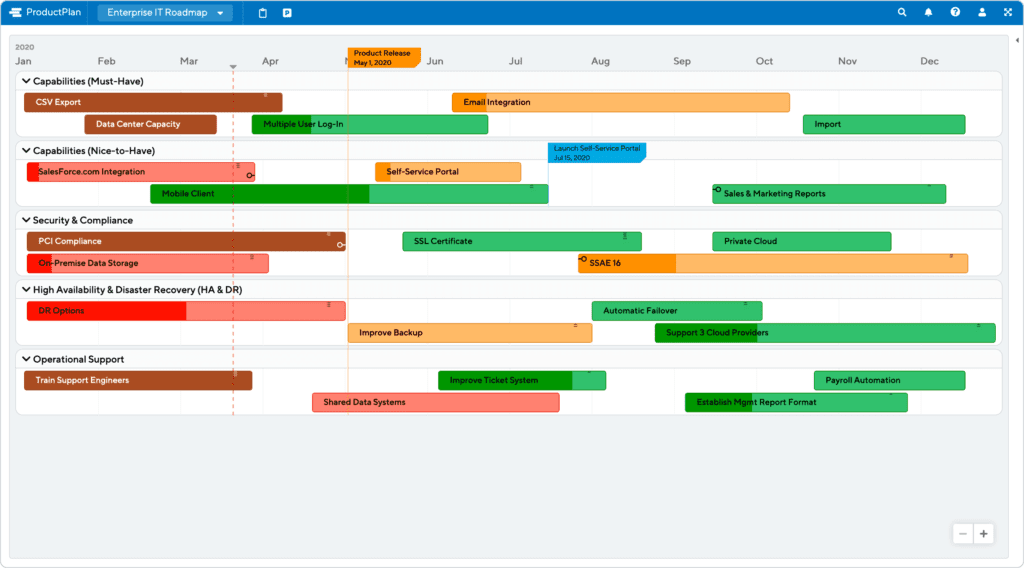

An example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina) In hot countries, salt is produced by allowing the sun to evaporate sea water in shallow pools or 'pans';The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demand Capacity planning strategies can guide manufacturers on how much raw materials, equipment, labor, and investment in facilities need to be acquired over a period of time to meet the future demand over products The IT strategy roadmap example section should describe the technology directions that will best support the business and a highlevel plan for getting there from the current state Because it can be difficult to foresee what new technology developments would benefit a given business, it's sometimes easy to go in a direction that ends up being wrong Therefore, an IT strategy

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

3 Types Of Capacity Planning Strategies Valq

At the individual level, it is useful to adapt strategic planning tools and technique to one's own job and position Thinking and planning 'strategically' at the personal level requires similar inputs, questions, and approach, and develops your capacity to participate in planning efforts for teams and higherlevel entities When strategic planning is done Within the UN, strategicCapacity Management Examples Todd is the manager of a company that produces paper sheets He evaluates the company sales and notices that the company is constantly selling 500,000 packages every month, which is its maximum capacity So, he decides to use a lead strategyStrategic capacity planning Sales and operations Planning (S&OP) Sales plan Aggregate operations planMedium Supply network planning Forecasting and demand management Master scheduling Material requirements planning Order scheduling Vehicle capacity planning Vehicle loading Vehicle dispatching Warehouse receipt planning Weekly workforce scheduling Daily

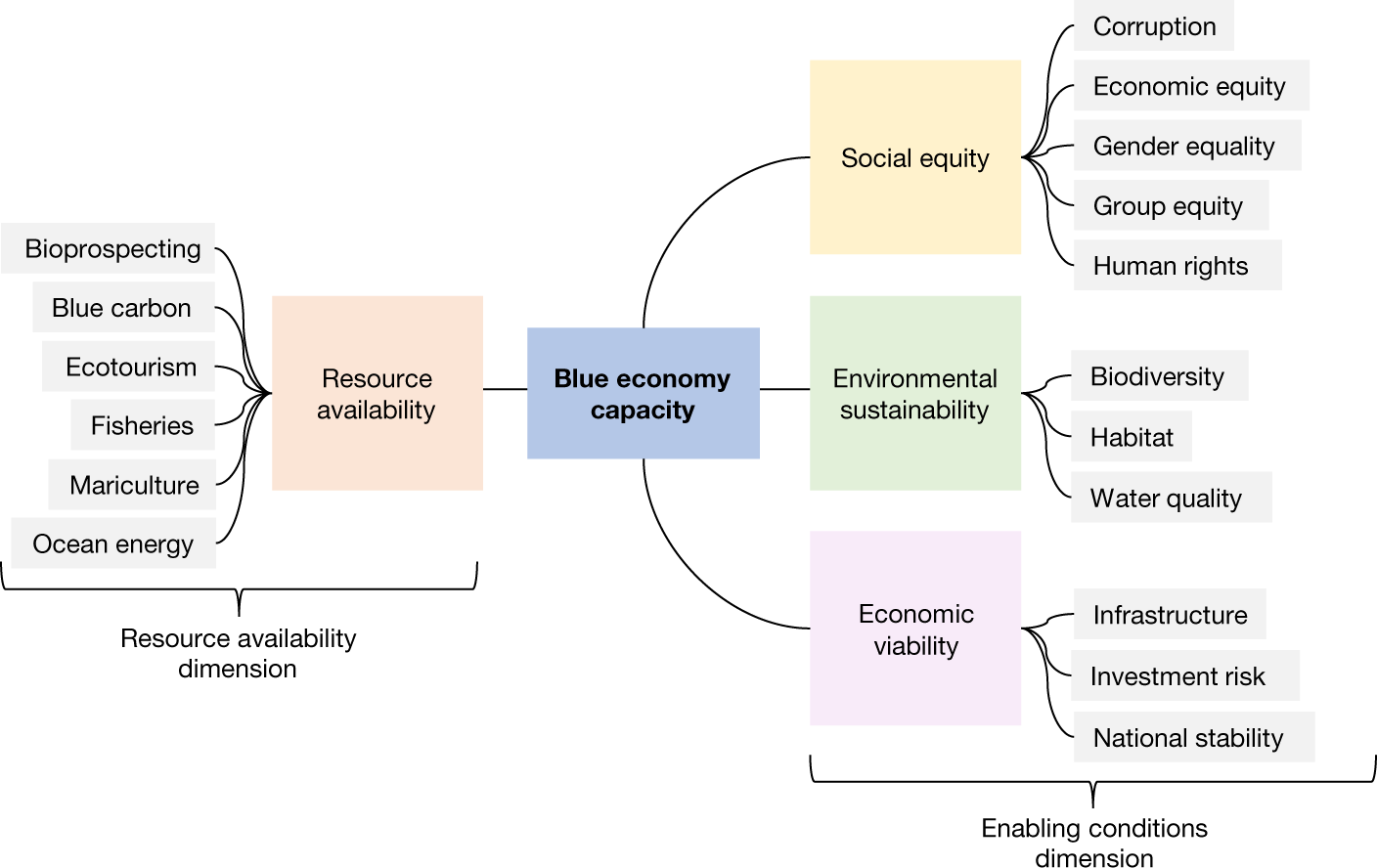

Enabling Conditions For An Equitable And Sustainable Blue Economy Nature

Long Term Capacity Management Linking The Perspectives From Manufacturing Strategy And Sales And Operations Planning Sciencedirect

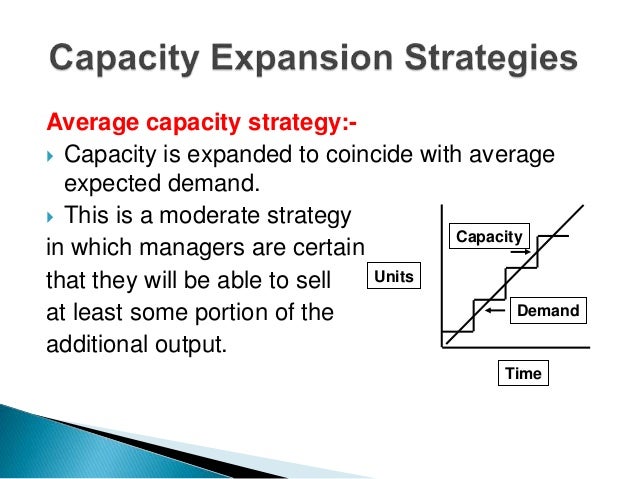

Aggregate capacity is the total amount of capacity required or available to carry out a function It also tells about the 3 best strategies for aggregate planningThey are level strategy, Chase strategy and hybrid strategy If Casey's company follows an average strategy for capacity, it'll align its capacity with the average expected level of demand forecasted For example, One of the strategic choices that a firm must make as part of its manufacturing strategy There are three commonly recognized capacity strategies lead, lag, and tracking A lead capacity strategy adds capacity in anticipation of increasing demand A lag strategy does not add capacity until the firm is operating at or beyond full capacity A tracking strategy adds capacity

Aggregate Capacity Planning Pdf Free Download

Subject 3 Capacity Management Subject 3 Gt Capacity Management 3 1 Capacity Management In Studocu

The goal of strategic capacity planningis to achieve a match between the longterm supply capabilities of an organization and the predicted level of longterm demand 3 Capacity Decisions are Strategic 1 Capacity decisions have a real impact on the ability of the organizationto meet future demands for products and services 2 Capacity decisions affect operating costs 3 CapacityExample of an objectives diagram and an impact diagram, in country evaluation Tanzania EN;Practical examples of models in capacity planning for different production modes include 1 Make to Stock (MTS) Make to Stock is common within discreet manufacturing and process manufacturing As these operations often have complex multilevel BOMs, capacity planning must include planning for subprocesses required to produce components

Capacity Planning 3 Methods How To Implement Them Optimoroute

1

Strategic capacity planning is how companies figure out the production capacity needed in order to meet consumer demand It's a highly difficult process because of several reasons The first reason is because it relies on accurate demand forecasting Most businesses do not do demand forecasting very well, often due to a lack of understanding of how to use the data The use of a chase strategy requires that a company have the ability to readily change its output level, which means that it must be able to readily change its capacity In some industries where labor is the major determinant of capacity, and where additional labor is readily available, such changes may be feasibleThis strategy is in line with the Regional Refugee Response strategy2 and country level plans It is essential for use by different stakeholders and it explores the relationship to existing mechanisms and programs The strategy is based on the three objectives linked to teacher training as stipulated in the Joint Refugee Education Response Plan namely;

Capacity Planning Everything You Need To Know Clicktime

Exhibit 4b Example Sourcing Decision Tree Tool Selection Considerations

About Strategy Mapping Balanced Scorecard Institute

Business Operations Overview Examples How To Improve

Capacity

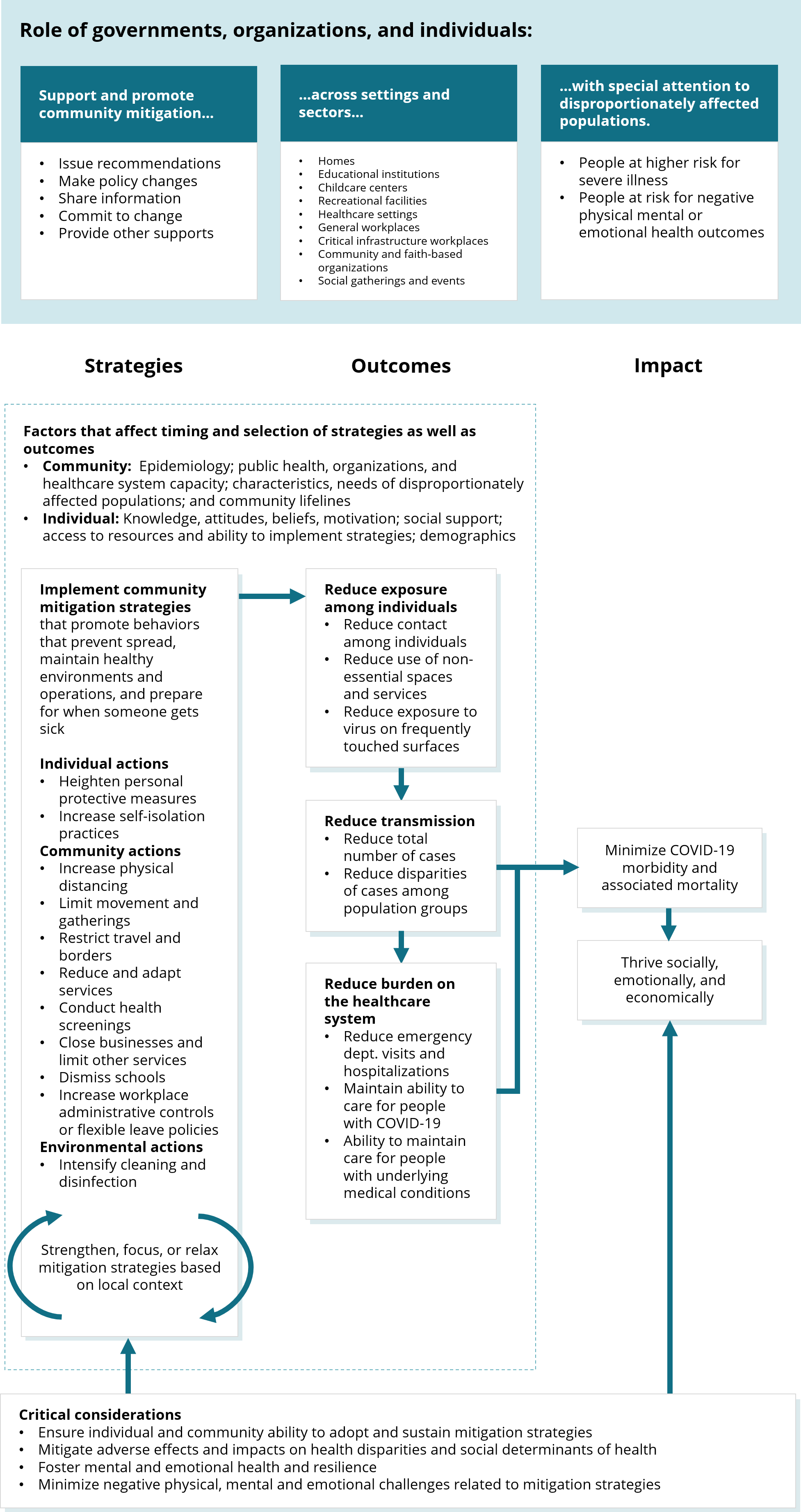

Guidance For Implementing Covid 19 Prevention Strategies In The Context Of Varying Community Transmission Levels And Vaccination Coverage Mmwr

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

1

Basic Strategies Level Capacity Strategy Chase Demand Strategy Ppt Download

Capacity Planning Meaning Strategies Importance And Procedure

Operations Strategy With Examples Studiousguy

04 01 P8 Hybrid Strategy Youtube

Capacity Planning 3 Methods How To Implement Them Optimoroute

How To Implement Business Capacity Planning Strategies Steps

Master Production Schedule

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

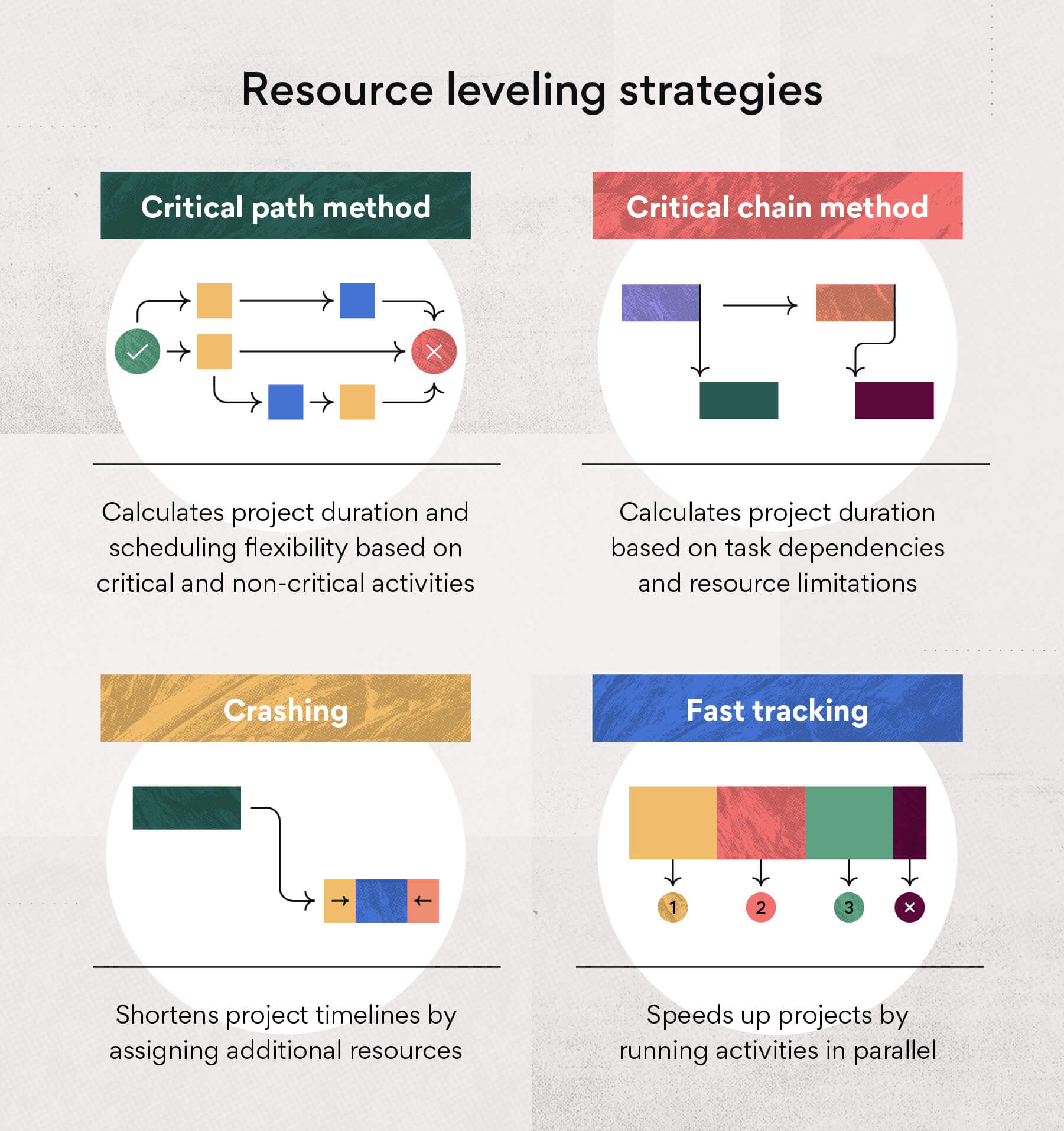

What Is Resource Leveling Techniques And Examples Asana

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Fast Track Strategic Planning For Nonprofits Nonprofit Essentials

Capacity Planning Everything You Need To Know Clicktime

3 Types Of Capacity Planning Strategies Valq

How To Implement Business Capacity Planning Strategies Steps

4 Capacity Strategy

Quick Guide How To Write A Strategic Plan Smartsheet

Operations Management Ppt Video Online Download

3

Aggregate Planning Definition Importance Strategies Management And Advantages

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

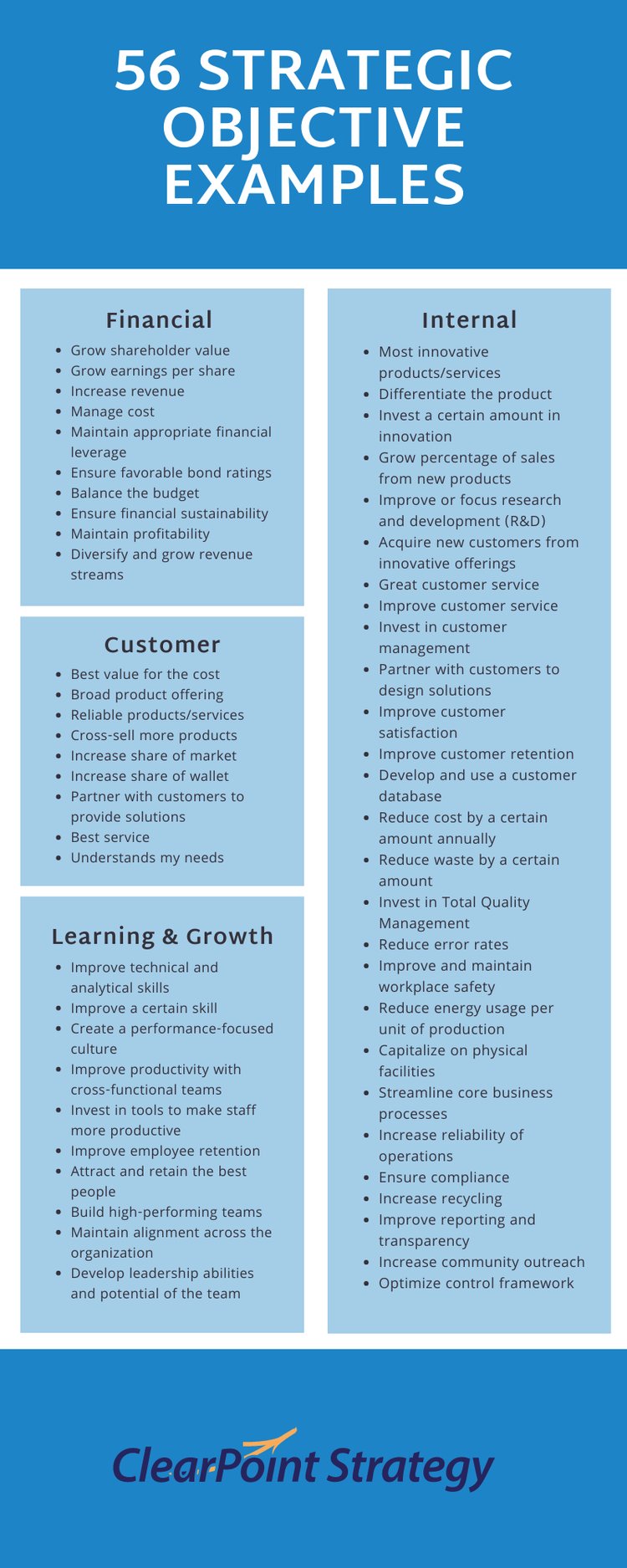

56 Strategic Objective Examples For Your Company To Copy Clearpoint Strategy

Capacity Planning Types Lead Lag Average Strategies Video Lesson Transcript Study Com

Solved Question 4 A Compare And Contrast The Level And Chegg Com

Capacity Planning Everything You Need To Know Clicktime

An Approach For Monitoring And Evaluating Community Mitigation Strategies For Covid 19 Cdc

How To Implement Business Capacity Planning Strategies Steps

What Is Aggregate Planning 3 Strategies For Aggregate Production Planning

Capacity Building Wikipedia

Distribution Strategy Cutting Edge Distribution Strategies 21

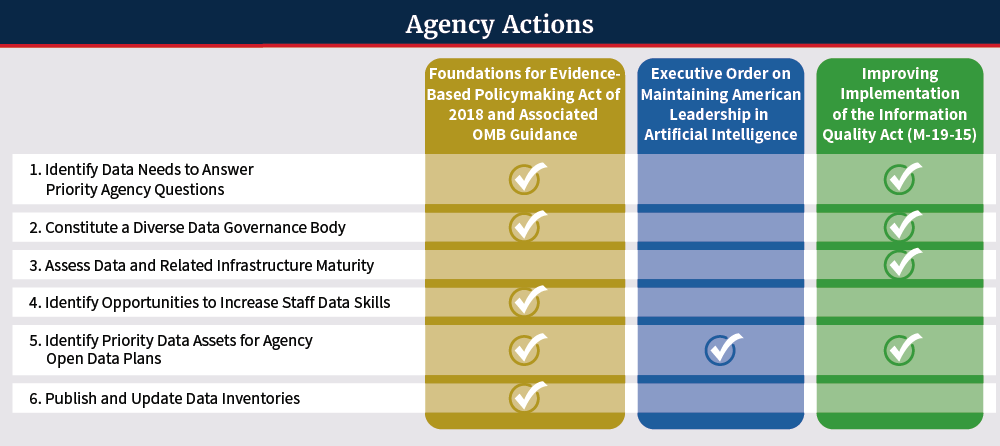

Action Plan Federal Data Strategy

7 Practical Ways To Prioritize Your Product Backlog

Strategic Themes Scaled Agile Framework

Everything About Capacity Planning Strategies Its Benefits

Operations Strategy Capacity Strategy Ppt Video Online Download

Operations Strategy With Examples Studiousguy

Strategic Capacity Planning Capacity Utilization

Lecture 4 Operations Strategy Lecture 4 Operations Strategy Klps Define The Term Operations Studocu

Capacity Planning And Control Ppt Download

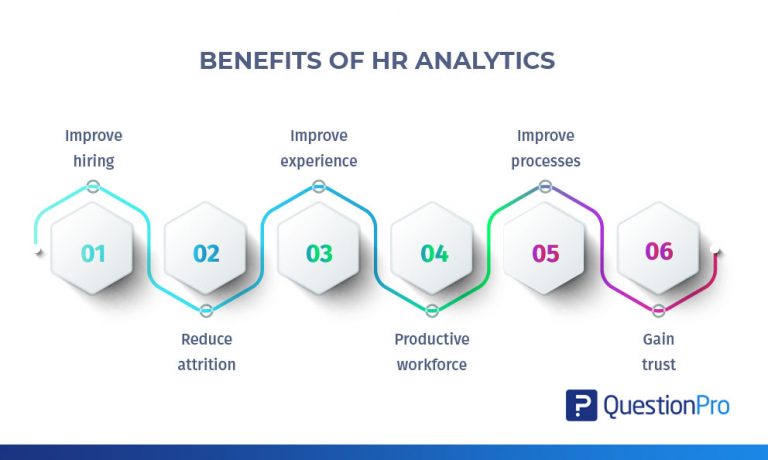

Hr Analytics Definition Example Hr Metrics Dashboard And Predictive Hr Analytics

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

4 Steps To Strategic Human Resource Planning Lucidchart

Everything About Capacity Planning Strategies Its Benefits

Maintenance Capacity Planning Ppt Video Online Download

Strategic Analysis Your Ultimate Guide Marketing Templates

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

Complete Guide To Strategic Implementation Smartsheet

What Is Resource Management And Why Is It Important Planview

Capacity Planning Meaning Strategies Importance And Procedure

What Is An It Roadmap Benefits And Roadmap Examples

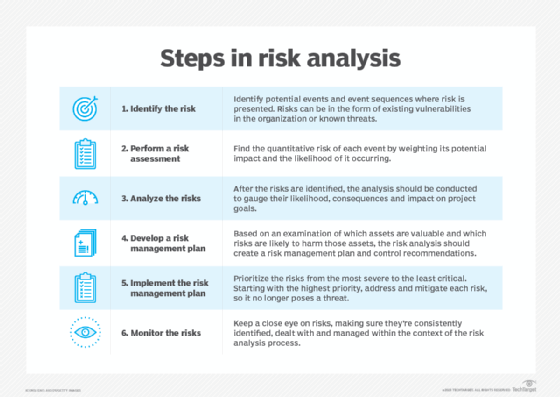

What Is Risk Mitigation Definition Strategies And Planning

3 Types Of Capacity Planning Strategies Valq

Capacity Strategy Some Factors Influencing The Overall Level Of Capacity Forecast Level Of Demand Consequences Of Over Under Supply Availability Of Ppt Download

Demand And Capacity Management Decision Steps Download Scientific Diagram

Master Production Schedule

What Is Resource Leveling Techniques And Examples Asana

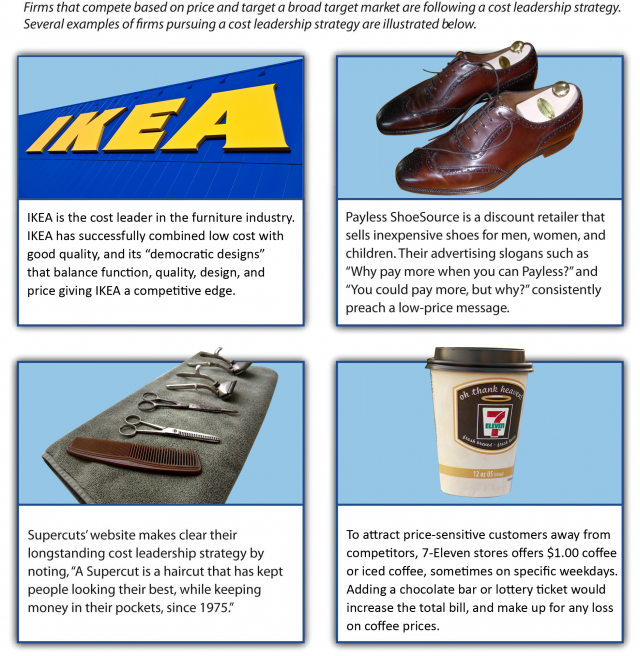

Cost Leadership Mastering Strategic Management 1st Canadian Edition

Capacity Planning 3 Methods How To Implement Them Optimoroute

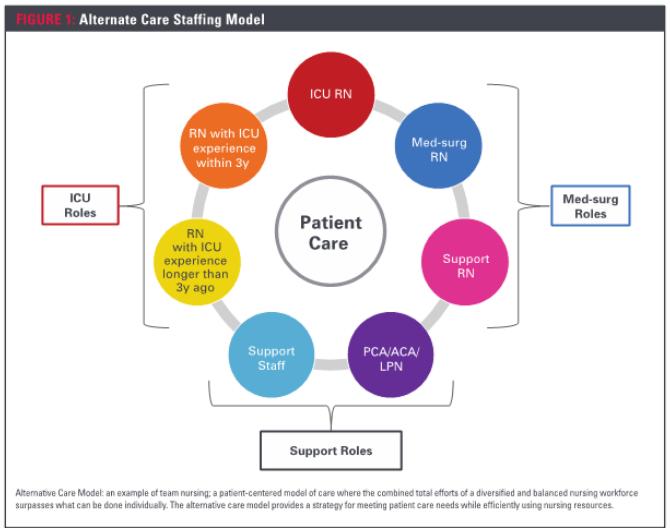

Building Capacity In A Pandemic An Alternate Staffing Model Aonl

.PNG)

Process Landscape Aris Bpm Community

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Network Based Social Capital And Capacity Building Programs An Example From Ethiopia Topic Of Research Paper In Sociology Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science Hub

Tor Wateraid

Capacity Utilization Manufacturing Kpi Examples Sisense

Operations Strategy Capacity Strategy Ppt Video Online Download

7 1 Capacity Planning Saylor Bus300 Operations Management

Entries For Thursday 25 October 07 Sergio S Blog

Strategy Under Uncertainty

Slides For Chapter 10 Strategic Capacity Honda On July 18 Announced Two New Plants In Argentina Honda Will Spend 100 Million On A New Compact Car Ppt Download

Question 1 A Single Automated Teller Machine Atm Is Chegg Com

Solved When Using A Level Capacity Strategy Or Level Chegg Com

Capacity Management

0 件のコメント:

コメントを投稿